Evaluation of Tablet

Evaluation of tablets or quality control tests for tablets is essential for determining the physical, chemical, biological, and mechanical properties of tablets based on various evaluation tests. The evaluation of tablets is necessary to check the tablet whether is comprised of all standards and gives beneficial effects for the prevention, mitigation, and treatment of any disease. In the world, there is various standardized book for every stream. like that in the pharmacy field, there is various pharmacopeia present. according to the different countries.

Eg: Indian Pharmacopeia, British Pharmacopeia, United State Pharmacopeia, European Pharmacopeia etc.

There is 2 type of evaluation parameter that takes into consideration

A. Non-official tests:

1. General Appearance

1.1 – Organoleptic properties

1.2 – Size and shape

1.3 – unique identification marking

2. Hardness test

3. Friability test

B. Official tests:

1. Weight variation test

2. Content uniformity

3. Dissolution test

4. Disintigration test

1. General appearance:

A tablet’s overall design and elegance are crucial for consumer acceptance. To identify and encourage patient compliance, a tablet’s appearance is essential. The measurement of a tablet’s shape, surface texture, diameter, thickness, color, absence or presence of an odor or taste, physical flaws, consistency, and legibility of any identification markings such as embossed or engraved with a logo or letter are all included in the control of a tablet’s appearance.

1.1 Organoleptic Properties:

The organoleptic characteristic includes the color, odor, and taste of the formulation. The color doesn’t affect the tablet’s appearance but sometimes the color is required to get patient compliance and increase the patient’s trust in medication. ( Example: we are taking some tablets which have a standard color like yellow, blue, and pink, etc. but sometimes tablets have colors like brown and black then the patient does not trust the tablet as such as they trust on comment color tablet.)

The taste matters in such a way that some drugs have bitterness in a test that is difficult to take and decreases patient compliance. To overcome this problem coating method is used.

Some tablet varieties, including chewable and ODT pills, have an odor to create a tasty flavor and increase patient acceptance. Flavoring agents are employed in coating materials to cover unpleasant smells, aside from some tablets.

1.2 Size and Shape:

A tablet’s thickness has an impact on both its size and shape. As a tablet grows larger, it becomes harder to administer, hence the size and shape of the tablet are critical factors in patient compliance. A micrometer caliper is an instrument that is used to measure a tablet’s thickness. If the batch is within 5% of the standard deviation, it may be considered acceptable.

1.3 Unique identification Marking:

Pharmaceutical companies use several some kind of distinctive markings, such as printing or embossing with a symbol or lettering on the tablet, for quick identification. To make breaking or creating a lesser dose easier, the tablets may be scored in halves or quadrants. Tablets with complete, distinct, and visible identification markings are permitted.

2. Hardness Test for Tablet:

The tablet is required some amount of hardness and strength. For this test, one of the earliest testers was Monsanto makes the Ketan tablet hardness tester, which is used for evaluating tablet hardness tester. The tester consists of a tube with a compressible spring placed between two plungers. The lower plunger is placed in connection with the tablet and zero reading is taken. The tablet eventually breaks as a result of the upper plunger being pushed up against a spring by rotating a threaded bolt. A pointer moves along a gauge in the barrel to measure the force as the spring is compressed. The force of the feature is recorded in kilograms.

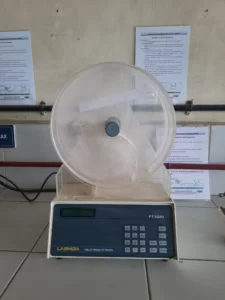

3. Friability Test for Tabet:

Friability testing for tablets is carried out to determine the durability of tablets. To check the friability of the tablet the Friabilator instrument is used. The friability consists of a plastic drum attached to a machine shaft that rotates at 25 revolutions per minute for 100 rotations. 20 tablets are taken into consideration for this testing. The 20 tablets are weight previous to the test. and then the tablet is put into Friabilator. After the revolutions remove the tablet from the stabilator. and weigh the tablet again. the weight variation must not be less than 0.5 to 1.0% for the conventional tablet.

Formula: Friability (%) = Initial weight (W1) – Final weight (W2) / Initial weight (W1) × 100

4. Weight Variation Test for Tablet:

The USP states that the weight variation test for tablets is conducted by weighing each of the 20 tablets separately, determining their average weight, and comparing those weights to the average. The weight variation test gives a percentage value.

| IP / BP ( Indian Pharmacopeia and British Pharmacopeia ) | Limit | USP (United Staes of Pharmacopeia) |

| 80 mg or less | ± 10% | 130 mg or less |

| more than 80mg and less than 250 mg | ± 7.5 % | 130 mg to 324 mg |

| 250 mg or more | ± 5% | more than 342 mg |

5. Content Uniformity Test for Tablet:

The term “content uniformity test for tablets” refers to the process of ensuring that each tablet has the amount of pharmacological material intended with little variance among tablets within a batch. The content uniformity test has been included in the monograph of coated or uncoated tablets, as well as all capsules designed for oral administration when the dosage form accessible ranges from 50 mg to smaller sizes. The tablet monograph includes standards for content consistency.

– Randomly select 30 tablets.

– 10 of these were assayed individually.

– If the tablet passes the test, 9 of the 10 tablets must contain not less than 85% and not more than 115% of the labeled drug content, and the 10th table may not contain less than 75% and more than 125 % of the labeled content.

– If these conditions are not met, the remaining 20 tablets are assigned individually and none may fall outside the 85 % to 115 % range.

6. Dissolution test for Tablet:

The dissolution test for tablets is important to check whether the tablet is dissolved properly inside the body fluid and gives a beneficial therapeutic effect. The test is performed in the dissolution apparatus. It consists of a rectangular basket with a no. of the cylindrical basket, a rotating shaft with a paddle, temperature regulator. put the individual tablet into an individual cylindrical tank / Basket. The cylindrical basket containing dissolution medium (Water, Simulated gastric or Intestinal ) at 37° C. Operate the apparatus at 50 rpm and take samples from the dissolution medium at intervals of time (10 to 15 ml every 10 min for half hr). pipette 2 ml of the sample and complete up to 50 ml of 0.1 N H2SO4 in a conical flask. Measure the absorbance by using a spectrophotometer at 228nm and apply the following equation.

C = Ab (Absorbance) X K(Consant) X Dillution Factor X Dissolution Medium

7. Disintegration test for Tablet:

The U.S.P. apparatus used for the disintegration test for tablets includes 6 glass tubes that are 3″ long; open at the top, and 10 mesh screens at the bottom end. One tablet is inserted in each tube and the basket is placed in a 1-L beaker of water, simulated gastric fluid, or simulated stomach acid to measure the disintegration time. intestinal fluid at 37 ± 20 C such that the tablet remains 2.5 cm below the surface of the liquid on its upward movement and not closer than 2.5 cm from the bottom of the breaker in its downward movement. Move the basket containing the tablets up and down through a distance of 5-6 cm at a frequency of 28 to 32 cycles per min. Placing perforated plastic discs on each pill will stop it from floating. The tablet must disintegrate in the time frame specified, and all fragments must pass through the 10 mesh screen. Any residue that is still present must have a soft mass.

another post:

B Pharmacy Syllabus 2023 Free To Download | PCI Approved